Implementation of Lean Engineering Practices in Projects and Programs through Simulation Based Training

Prof Avraham Shtub, PhD

Technion Israel Institute of Technology, Haifa, Israel

Michal Iluz

Rafael Advanced Defense Systems LTD., Haifa, Israel

Kilian Gersing

Massachusetts Institute of Technology

Cambridge, MA, USA

Prof Josef Oehmen, PhD

Massachusetts Institute of Technology

Cambridge, MA, USA

Yael Dubinsky, PhD

Haifa Research Lab, Haifa, Israel

Abstract

Teams in engineering projects face complex decisions on a daily basis. In order to meet or exceed stakeholders' needs and expectations project teams must plan and re-plan their project to keep it on track. Their decisions are made in an uncertain, dynamic and constrained environment spanning a large variety of areas such as outsourcing decisions, design decisions, risk management decisions, resource related decisions, budgets and schedule related decisions etc.. Their purpose is to lower cost, reduce rework minimize paperwork, and eliminate duplicate efforts. Teamwork is essential in this challenging environment and a shared understanding of the project goals and constraints is the foundation of teamwork.

This paper describes our experience in using Simulation Based Training (SBT) and in particular, its contribution to the implementation of Lean Management Practices (“Lean Enablers”) among project team members and stakeholders in two different industries in order to lead to better project outcomes in terms of time, performance, cost, and stakeholders' approval.

1. Introduction

a. Lean Enablers

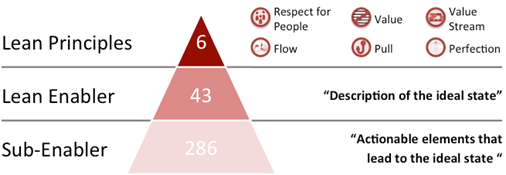

The Lean Enablers are a set of Lean best practices, which have been developed specifically for the improvement of large-scale engineering programs. There are 43 Lean Enablers in total, which are sorted according to the six Lean Principals (value, value stream, flow, pull, perfection, respect for people) as shown in Figure 1 [1].

Figure 1: Lean Principals, Lean Enablers and Sub-Enablers

The following section will introduce each of the Lean Principles in a little more detail [1]–[3]:

1. Respect for People – Seeing employees as the most important and valuable resource is critical for creating a high-performance working environment. The Lean methodology suggests encouraging the people to honestly address problems and obstacles, find out their root causes, collaboratively develop corrective actions and find a common consensus to prevent such problems in the future.

2. Value – It is important to capture the value defined by internal and external customer stakeholders, the external customer being the one who defines the final value of the deliverable.

3. Value Stream – The entire value stream needs to be mapped in order to identify and eliminate all non-value-adding activities, minimize all necessary but non-value-adding activities and make sure that all value-adding activities can flow without rework, backflow, or stopping.

4. Flow – In engineering programs, information should be able to flow from value-adding steps in streamlined process without stopping, unplanned rework, or backflow. Among the necessary conditions to achieve the state of perfect flow is a detailed capture of customer value, a good enterprise-level preparation, as well as an effective program planning.

5. Pull – The costumer stakeholders must pull the value. This implies two important meanings: Firstly, any task in a program must meet a specific need by a customer stakeholder. Any other task must be carefully examined and eliminated in case it is unnecessary. Secondly, every task must be delivered exactly when the customer stakeholder requires it. Early completion can lead to wasteful complications through e.g. the loss of human memory or a change in requirements.

6. Perfection – It is important to pursue perfection of products and processes. The degree of perfection for the product, or the output of a process, need to meet the value proposition, which defines when an output is good enough.

The first Lean Enabler of the first Principle, for example, states: “Build a program based on respect for people”. The first Subenabler of this Enabler then states, “Understand that programs fail or succeed primarily based on people, not processes. Treat people as the most valued assets, not as commodities.” The Subenablers give more details on what needs to be undertaken in order to fully implement the Lean Enabler. The Guide to Lean Enablers for Managing Engineering Programs (Oehmen et al. 2013) furthermore gives a number of examples for each Lean Enabler, shows which program performance domain the Lean Enabler is relates to, indicates which challenge the Lean Enabler addresses and also links each Lean Enabler to the appropriate process number of the systems engineering process.

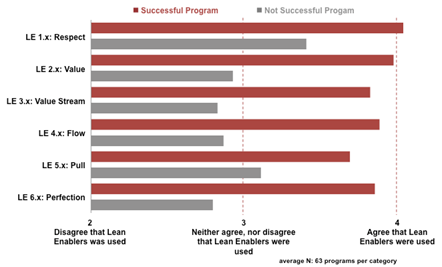

In order to determine the impact of the Lean Enablers, “best in class” programs were analyzed for the use of Lean Enablers. The result of this analysis was, that the three most highly successful programs, on which the amount of detailed information was enough for the analysis, used 60% to 75% of all the Lean Enablers. After the rough analysis, a second, more detailed analysis was conducted, based on a survey, in which the performance of successful and unsuccessful programs, as well as the degree to which they used the Lean Enablers was asked. The strong results of the survey showed, that successful programs have more Lean Enablers implemented than unsuccessful ones. Figure 2 summarizes the results of the survey and clearly emphasizes the difference in performance between successful and unsuccessful programs [4].

Figure 2: Successful program show significantly higher performance than unsuccessful programs

b. Simulation Based Training and the Project Team Builder Simulator (PTB)

The essence of Simulation Based Training is that we must do things ourselves in order to really understand them. In his article, James I. Grieshop [Grieshop 1987] stated that: "Games and simulations (ranging from role playing to case studies, from guided fantasy to problem solving) have become widely recognized methods for instruction and learning. Since the early work in the United States in the late 1950s and in Europe in the late 1960s, gaming/simulation has become increasingly important to training and decision-making processes in academic settings as well as in business, the military, and the social sciences."

Simulation Based Training (SBT) is a powerful tool that can be employed for training the Lean project principles. We found SBT to be instrumental in the creation of shared understanding among team members and, in addition, to improve tradeoff analysis and decision-making. Our pilot study in RAFAEL and IBM suggests that SBT can be used effectively to build project teams. Teams can be trained using SBT with a focus on the real project assigned to the team. By simulating a scenario based on the real project, the team can learn how to integrate the different aspects of project management, and – more importantly – can learn to work and solve problems together.

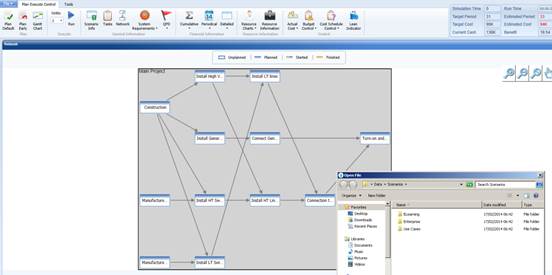

The Project Team Builder (PTB) http://www.sandboxmodel.com/ is a simulation based training simulator for Project Management. The simulator includes a pool of scenarios arranged according to their level of difficulty. Below is a screenshot of this scenario pool – Figure 3:

Figure 3: Scenarios pool

The PTB simulator includes a module for requirements management that supports the process of selecting alternative designs that determine system performance. Trainees have the option of interactively experiencing the decision making process. They have the opportunity to cope with the project execution resulting from these decisions.

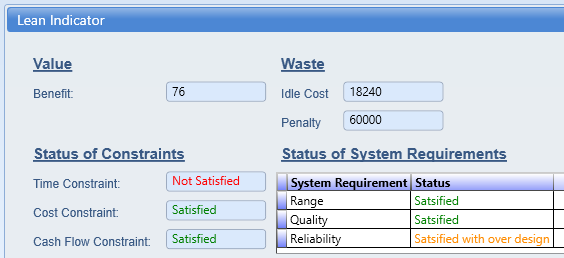

A lean indicator report built into the Project Team Builder present the sources of waste and the value generated by the project. The value is calculated as a weighted sum of customer requirements based on the Quality Function Deployment (QFD) logic.

The lean indicator report identify infeasibilities in project scope (due date violation, budget violation and cash flow violation), as well as violation of product scope (requirement that are not satisfied and gold plating or overdesign of products with respect to some requirements). The Lean Indicator report is presented in Figure 4.

Figure 4: Lean Indicator report

In Figure 4 the value to the customer is 76% while there are two sources of waste: Idle cost of resources and a penalty for late delivery. The due date or time constraint is violated i.e. the project is late and the requirements are all satisfied although the last one (Reliability) is gold plated or over designed.

2. Using PTB in Workshops in R&D Organizations

This section describes our experience using a simulator for training Program in industry. We conducted two types of workshops in RAFAEL and IBM. Attendees were managers in different Research and Development (R&D) settings.

Rafael Advanced Defense Systems Ltd. develops and produces state-of-the-art defense systems for the Israel Defense Forces (IDF) and Israel's defense system. The company provides innovative solutions on the technological cutting edge from underwater, naval, land and air through space systems. RAFAEL focuses on such areas as Electronic Warfare (EW), Command, Control, Communications, Computers and Intelligence (C4I), training and simulators, armor and precision-guided weapon systems. The company has also formed partnerships with civilian counterparts to develop commercial applications based on its proprietary technologies. Rafael is the second largest government-owned defense company in Israel.

The IBM Haifa Research Laboratory (HRL) (http://www.haifa.il.ibm.com/) is IBM's largest research laboratory outside of the United States, employing almost 500 researchers, the majority of whom hold PhD and master's degrees in computer sciences, electrical engineering, mathematics, and related fields. Since its founding in 1972, HRL has conducted research vital to IBM's success. R&D projects are being executed today in areas such as healthcare and life science technologies, telco, machine learning, mobile, cloud computing, multimedia, information retrieval, programming environments, and optimization technologies.

Methodologies for simulation-based training have been developed and 2 types of workshops have taken place:

· Full one day, or two days workshop including lectures and hands-on experience where participants build a scenario based on a real project with the goal of maximizing performance under schedule ,cost, quality and resources constraints based on Lean PM methodology.

· Before the project starts (the Fuzzy Front End of the Project) project teams are trained by PTB how to implement the Lean development methodology on their real-life future project. Team members learn how to evaluate the alternative plans for the project. An efficient frontier of project plans is generated by PTB and the team members learn how to trade off cost, benefit and duration and to find the best plan for their project.

The workshops were successful, both in terms of professional enrichment and in providing information to the participants, including familiarity with the Lean principles and in terms of building a team, creating communication and creating a common language amongst team members, shared understanding of targets and goals of the project.

Some insights gained from the workshops are:

1. The workshop is suitable for various levels of experience, both experienced and inexperienced PM's and SE's. The workshop can be conducted in variable class sizes (8-40 participants).

2. Hands-on experience and training can be achieved rapidly even within a day. Expanding the time frame to two days allows better training and increased levels of experience, which can be attained by tapping into higher levels of the tool's capabilities (for example in a two days workshop participants created their own scenarios and simulated the scenarios on the PTB).

3. Participants learned how to work with the tool and could subsequently continue to work individually to achieve the desired level of expertise.

4. The tool contributes to creating shared understanding and to amalgamating team members towards their joint work on the real project.

5. Providing feedback during the workshop regarding the team's achievements and analyzing the results of their decision-making indeed illustrates the Lean principles and contributes to the understanding as to where the team can be more productive, eliminate waste and improve.

6. The workshops using this tool demonstrated the technical and the managerial aspects (i.e., the integration of the system engineering world with the world of project management) within one integrative picture of the project and ties together three measures of project success (duration, cost and performance) within the world of Lean principles.

3. Process of mapping Lean Enablers to PTB capabilities

According to (Gersing 2013) the process of evaluating the overall value of simulations for the implementation of Lean Enablers is done through a five-step utility value analysis, which is based on [5], [6, p. 175]:

1. Determination of target criteria

2. Weighting of each target criterion

3. Calculation of partial utility values

4. Calculation of (total) utility values

5. Assessment of profitability

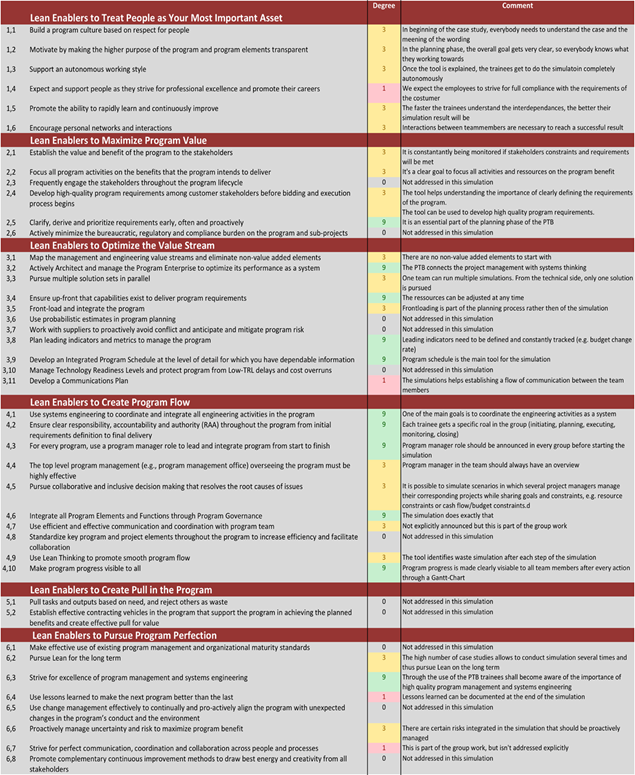

Since the purpose of the simulation is to address and implement the Lean Enablers, the target criteria in this utility value analysis is implementing the Lean Enabler itself. The weighting is kept very simple by assuming, that if a Lean Enabler is supposed to be implemented the degree of importance of the target criterion is weighted as “one” or 100%, and if not then “zero” 0%. In order to calculate the partial and the total utility value of a simulation, it is necessary to determine to which degree the simulation addresses each Lean Enabler. For this determination, a solid five-step process was designed, which resulted in an accurate and detailed mapping. Figure-5 shows this process.

Figure 5: Five-step process for the determination of the degree of fulfillment of a simulation

Several simulations were mapped this way, including the PTB-Simulator. For this paper only the PTB is of relevance. The first step was the active participation in a workshop where the PTB was directly applied. This was considered necessary in order to deeply understand how the demonstration tool worked and what it covered. In the next step, the degree to which the PTB addressees or implements each specific Lean Enabler was estimated. The scale for the degree was chosen as follows:

· 9: Demonstration Tool directly addresses the Lean Enabler

· 3: Demonstration Tool indirectly addresses the Lean Enabler through how it is done

· 1: Demonstration Tool barely addresses the Lean Enabler

· 0: Demonstration Tool doesn't address the Lean Enabler

This preliminary estimation was then validated in a first round interview with an expert on the PTB. In the next step the suggestions from the expert were implemented in the mapping. Finally the mapping was validated win a second round interview. The mapping can be seen in the Appendix.

4. Selection of Lean Enablers for the workshop

As a result to the process explained in the previous chapter, it was evaluated that the following Lean Enablers were addressed directly by the PTB-Simulator and thus can be implemented through its use. The first number in front of each Enabler indicates the Lean Principle and the second the number for the Enabler in the Principle.

· 2.5: Clarify, derive and prioritize requirements early, often and proactively

· 3.2: Actively architect and manage the Program Enterprise to optimize its performance as a system.

· 3.4: Ensure up-front that capabilities exist to deliver program requirements

· 3.8: Plan leading indicators and metrics to manage the program

· 3.9: Develop an Integrated Program Schedule at the level of detail for which you have dependable information

· 4.1: Use systems engineering to coordinate and integrate all engineering activities in the program.

· 4.2: Ensure clear responsibility, accountability and authority (RAA) throughout the program from initial requirements definition to final delivery

· 4.3: For every program, use a program manager role to lead and integrate program from start to finish

· 4.6: Integrate all Program Elements and Functions through Program Governance

· 4.10: Make program progress visible to all

· 6.3: Strive for excellence of program management and systems engineering

The main result of the mapping is, that these 11 Lean Enablers can be implemented very well using the PTB-Simulator.

5. Summary

Confucius said: "I hear and I forget. I see and I remember. I do and I understand."

We have to experience some things on our own in order to really understand them.

In this paper we discuss ideas, tools and techniques that can help project managers, project team members and Systems engineers cope with the implementation of the Lean Enablers. We focus our discussion on the Lean Enablers which can be measured and employ training using SBT and specifically the PTB simulator.

Implementing lean management originated in improving the competitiveness of the organization by streamlining and improving processes within the organization, and achieving rapid and substantial savings in operating costs.

The initial steps for implementing and achieving improvements lie in understanding the Lean principles, the Lean Enablers and implementing the tools and techniques of the Lean methodology.

The simulation-based learning workshop supports the study of Lean project management principles in a complex uncertain environment.

Appendix: Mapping of the Lean Enablers to the PTB

References

[1] J. Oehmen, B. Oppenheim, E. Norman: Lean Enabler for Managing Engineering Programs, 1.0 ed. Cambridge: Joint MIT-PMI-INCOSE Community of Practise on Lean in Program Management, 2012.

[2] Y. Sugimori: Toyota Production System and Kanban System: Materialization of Just-in-time and Respect-for-human System. 1977.

[3] J. P. Womack and D. T. Jones: Lean Thinking. New York, Free Press, 2003.

[4] M. Steuber: Success Criteria and Enablers for the Management of Engineering Programs, 2012.

[5] K. Gersing: Systematic Implementation of Lean Thinking in Engineering Programs, 2013.

[6] U. Götze, D. Northcott, and P. Schuster: Investment Appraisal: Methods and Models. Springer, 2007.

[7] Grieshop, James I. "Games: powerful tools for learning." Journal of Extension 25.1 (1987).

ACKNOWLEDGMENT

This research was supported by the Bernard M. Gordon Center for Systems Engineering at the Technion—Israel Institute of Technology.

x

About the Authors

![]()

Professor Avraham

Shtub

Professor Avraham

Shtub

Haifa, Israel

![]()

Professor Avraham Shtub holds the Stephen and Sharon Seiden Chair in Project Management. He has a B.Sc from the Technion - Israel Institute of Technology, an MBA from Tel Aviv University and a Ph.D from the University of Washington. He is the recipient of the Institute of Industrial Engineering 1995 "Book of the Year Award" for his Book "Project Management: Engineering, Technology and Implementation" (co-authored with Jonathan Bard and Shlomo Globerson), Prentice Hall, 1994. He is the recipient of the Production Operations Management Society 2000 Wick Skinner Teaching Innovation Achievements Award for his book: "Enterprise Resource Planning (ERP): The Dynamics of Operations Management" and he is the recipient of the 2008 Project Management Institute Professional Development Product of the Year Award for the training simulator "Project Team Builder – PTB". His books were published in English, Hebrew, Greek and Chinese. He can be contacted at shtub.avraham@gmail.com.

Michal Iluz

Haifa, Israel

![]()

Michal Iluz is a researcher at Rafael Advanced Defense Systems Ltd., Haifa, Israel. Michal Iluz received her B.Sc. in Industrial Engineering and Management and M.E. in Systems Engineering in 2001 and 2008, respectively from the Technion – Israel Institute of Technology, Haifa, Israel, where she is currently working towards a Ph.D. degree at the Industrial Engineering and Management Faculty. For the past 15 years Michal has gained vast experience in complex project management in the defense industry. Her current research interests include simulator-based decision making, shared understanding and implement of lean management techniques. Email: micahli@rafael.co.il

Prof Dr. Josef Oehmen

Massachusetts, USA

![]()

Prof. Dr. Josef Oehmen is a researcher at the Sociotechnical Systems Research Center, Massachusetts Institute of Technology, Cambridge, Massachusetts, USA. Josef is also an Associate Professor at the Engineering Management Department of the Technical University of Denmark, as well as a Research Affiliate of the Massachusetts Institute of Technology. Josef holds a master’s degree in mechanical engineering from the Technical University of Munich, an MBA from the Collège des Ingénieurs in Paris, and a PhD from the Swiss Federal Institute of Technology (ETH Zurich). His research interests focus on the management of large-scale engineering programs, particularly on the application of lean management techniques and risk management. Josef is the recipient of the 2012 Shingo Award for his book “The Guide to Lean Enablers for Managing Engineering Programs”, as well as numerous other awards for his work on engineering program management and risk management. Email: oehmen@mit.edu

Dr. Yael Dubinsky

Haifa, Israel

![]()

Dr. Yael Dubinsky is a researcher on system and software engineering at Haifa Research Lab, Haifa, Israel. Dr. Dubinsky is affiliated with the Emerging Quality and Design Technologies Department in IBM Research - Haifa (HRL). For more than ten years she is also the instructor of project-based courses at Technion IIT. She has published her work at conferences and journals related to software engineering and information systems, and facilitated workshops and tutorials in leading conferences. Yael has a significant experience with guiding agile implementation processes in the industry and academia. Her book on Agile Software Engineering, which she co-author with Orit Hazzan, was published by Springer at 2008. Email: dubinsky@il.ibm.com

Kilian Gersing

Massachusetts, USA

![]()

Kilian Gersing is a researcher at the Consortium for Engineering Program Excellence at the Massachusetts Institute of Technology, Cambridge, Massachusetts, USA. Kilian holds a master’s degree in mechanical engineering from the Technical University of Munich (TUM). Last year he wrote his master’s thesis as a visiting student at MIT as part of the Consortium for Engineering Program Excellence. The focus of his research lied on the development of workshops and executive trainings for the implementation of Lean Thinking in large-scale engineering programs. Before going to MIT, Mr. Gersing gained significant work experience in internships at the BMW AG in Munich and the Robert Bosch GmbH in Shanghai. Since 2012 he has been collecting entrepreneurial experience as the co-founder of InnoMotions, a technology start-up in Munich, which closely cooperates with BMW. After finishing his studies, he became head of InnoMotions. Email: gersing@mit.edu